Services

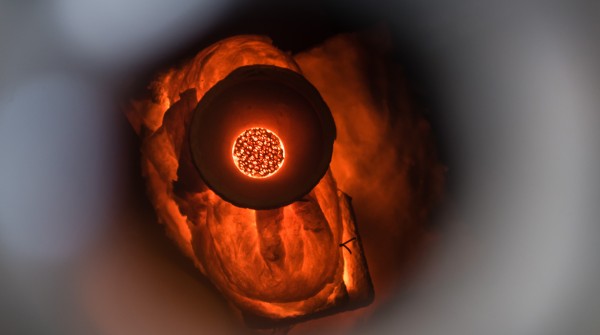

The BES Manufacturing part consists of three main shop: investment casting, machining, and coating , enabling the production of various advanced industrial components needed in different industries. The main production areas in the Badr System are industrial gas turbine component and aviation/ aero engine. In addition, the flexible manufacturing system (FMS) allows for the manufacturing of parts with high complexities in other industries. Also The BES is certified for the production automotive, , marine, oil and gas, petrochemical, and other components. investment Casting shop: The investment casting unit is the primary production line in the Badr System, with the capability to produce various parts ranging in weight from 10 grams to 100 kilograms, and with a wide range of alloys, from special alloys to nickel and cobalt-based super alloys. This station is equipped with various induction furnaces under vacuum for melting various super alloys. Machining shop: The machining line of Badr System includes various types of, CNC milling and turning machines, EDM (Electrical Discharge Machining) equipment, grinding machine and other facilities continues its production activity in its three areas : - Designing and manufacturing various tools required for other shop of the factory. - Production of components through machining. - Machining of cast parts. The machining line, equipped with comprehensive machinery and specialized technical personnel, operates independently of any outsourcing for the production of parts. Finishing and Coating: All produced components in Badr System require additional finishing operations based on their functional process type. These operations are carried out at four different stations : - Heat Treatment shop - Rework Shop - Cleaning Shop - Coating Shop.

"At BES, we are more than just manufacturers of gas turbine blades and vanes; we are pioneers in the field of know-how generation. Our expertise goes beyond production, encompassing comprehensive consulting, engineering services and technology transfer. With years of experience and a profound understanding of the industry, we have amassed invaluable expertise in producing these critical components. Our consulting services are designed to share this wealth of knowledge, enabling us to collaborate with clients in driving innovation and achieving excellence. With a dedicated team of experts, we excel in seamlessly transferring this invaluable data to our customers. This means you not only receive meticulously crafted components, but also gain access to the insights and expertise that have propelled us to the forefront of the industry. Whether you're looking to optimize existing processes or embark on a new venture, our consulting and engineering services are tailored to meet your specific needs. Together, we can elevate your projects to new levels of precision and efficiency.

Maintenance/Repair/Overhaul (MRO)

Procurement and supply

QC & Laboratory

Products

Aero-Engines

Badr System Company has been actively engaged in the aerospace industry for years, with a focus on pushing technological boundaries. The production of highly sensitive aerospace components, including internal parts for commercial, military, and transport aircraft engines, is the result of years of research and development in this facility. Some of the company's aerospace products include stationary and moving blades, various types of guide vanes, APU and GPU components. Aviation standards, and certificates, along with a precise quality control system at the Badr System facility, ensure the quality of the produced products..

Gas Turbines

Badr System is an innovative company with over 30 years of experience in the production of both stationary and rotating parts for industrial gas turbines component. The BES manufactures components for various types of gas turbines, including those from general electric ,Siemens, Westinghouse, Mitsubishi, Hitachi, Alstom, Workspace, BBC, Ruston, and others, which have been actively used in power generation, oil and gas, and petrochemical industries for years. The quality of the products produced by this company is certified. To date, over 50 different components, including stationary and moving blades, combustion chamber parts, and others, have been manufactured in the BES...

About Badr System Engineering Company

Badr System Engineering Company is a knowledge-based company that was founded in 1371 with the aim of expanding knowledge in the field of compiling technical knowledge and manufacturing Hi-Tech parts. Paying special attention to compiling technical knowledge in Iran, as an alternative solution to the method of buying ready-made technical knowledge from other countries, has been one of the main features of Badr System Engineering Company since its establishment.

News, events and articles

Public Relations of Badr System Company

Latest news: Badr System Engineering Company is a knowledge-based company with the aim of expansion Danesh has been established in the field of compilation of technical knowledge and manufacturing of Hi-Tech parts in 1371.

The last event

The newest turbine was put into operation by Sepahan Turbine Company

The newest turbine was put into operation by Sepahan Turbine Company

The last article

For the first time, researchers at Berkeley University succeeded in bu...

For the first time, researchers at Berkeley University succeeded in building a turbine with the highest speed